З дисципліни «Міжнародні корпорації в умовах глобалізації»

|

|

Індивідуальне завдання №1

З дисципліни «Міжнародні корпорації в умовах глобалізації»

Ознайомтесь з матеріалом кейсу, складіть до нього питання англійською мовою та перекладіть весь матеріал на українську мову. Завдання оцінюється у 5 балів. Кейс можете обирати будь-який. Основна умова, щоб кейси у групі не повторювалися.

ЗМІСТ

A Siemens case study “MEETING GLOBAL AND LOCAL NEEDS”. 2

A Vodafone case study “USING TECHNOLOGY TO IMPROVE ECONOMIES”. 8

A Cadbury Schweppes case study “FINANCIAL STATEMENTS AND REPORTING” 15

A Nestlé case study “SUSTAINABILITY AND WATER”. 22

A Nissan case study “PLANNING FOR QUALITY AND PRODUCTIVITY”. 28

A McDonald's Restaurants case study “RECRUITING, SELECTING AND TRAINING FOR SUCCESS”. 34

A Coca-Cola Great Britain case study “WORKING WITH BOTTLING FRANCHISEES AROUND THE WORLD”. 39

A Levi's case study “RECLAIMING THE IDENTITY OF A BRAND”. 46

A Ben Sherman case study “USING THE MARKETING MIX IN THE FASHION INDUSTRY”. 51

A Shell case study “TAKING A LONG-TERM VIEW - DEVELOPING FUELS FOR THE FUTURE”. 58

A UNISON case study “USE OF PEST ANALYSIS AT UNISON”. 63

An Amway case study “REACHING CUSTOMERS THROUGH DIRECT SELLING” 69

An IKEA case study “SWOT ANALYSIS AND SUSTAINABLE BUSINESS PLANNING”. 76

A Siemens case study

“MEETING GLOBAL AND LOCAL NEEDS”

Introduction

Siemens AG is a global electrical and electronics business with a turnover of £53 billion. The business employs over 450,000 people. The company base is in Munich, Germany. From there, executives oversee work carried out in the name of Siemens all over the world.

In the UK, Siemens plc has its headquarters in Bracknell, Berkshire and has more than 100 offices and factories. It employs more than 21,000 staff, 5,000 of these in manufacturing. There is hardly an aspect of our lives that is not touched by the company's work.

We can toast bread in a Siemens toaster powered by electricity generated and distributed by Siemens, travel on a Siemens train or pass through Siemens traffic lights in a car, which uses Siemens technology. People in hospital are having life saving MRI scans using Siemens advanced medical imaging technology.

Siemens is a multi-sector business. The business specialises in finding new ways to improve our quality of life and work. Businesses, health service trusts, local authorities, government and government agencies all use Siemens expertise. This expertise includes ICT, healthcare, transport and energy.

The UK business has a turnover of more than £3 billion and contributes £96.2 million profit to the group. Siemens contributes significantly to the UK economy and provides a huge variety of jobs.

Globalisation

'Globalisation' refers to the trend where individual countries become less influential in relation to crossnational bodies. People worry we are turning into one global 'village'. Decision makers are far away. There is fear because such decisions do not take note of what local people need or want. However, as the case study will show, meeting local needs is key to the performance of a business like Siemens'.

Siemens is multi-national. It operates across 190 separate nation states. Executives in Germany and across the world must make decisions in the best interests of Siemens' shareholders. Most multinationals have many capabilities. They must make decisions about where their separate activities should be. For Siemens it is not efficient to design and manufacture all products in all countries. It is more efficient to concentrate manufacturing to keep economies of scale through specialisation. Products can be shipped anywhere within the group.

Siemens is multi-national. It operates across 190 separate nation states. Executives in Germany and across the world must make decisions in the best interests of Siemens' shareholders. Most multinationals have many capabilities. They must make decisions about where their separate activities should be. For Siemens it is not efficient to design and manufacture all products in all countries. It is more efficient to concentrate manufacturing to keep economies of scale through specialisation. Products can be shipped anywhere within the group.

One danger of being multi-national is the threat caused by currency fluctuations. The price of products supplied from one place to another can vary because of currency changes. The value of the Euro can rise against the US dollar. In Europe, Siemens then becomes more expensive than US competition. It has an internal risk management function to check this threat. Steps can be taken to avoid its damaging effects.

One danger of being multi-national is the threat caused by currency fluctuations. The price of products supplied from one place to another can vary because of currency changes. The value of the Euro can rise against the US dollar. In Europe, Siemens then becomes more expensive than US competition. It has an internal risk management function to check this threat. Steps can be taken to avoid its damaging effects.

Globalisation presents many challenges to Siemens. How does Siemens in the UK remain an efficient part of the global business? How does it ensure that it continues to contribute to Siemens' overall mission, as it has done for 162 years?

One way of securing the UK business is by making sure that Siemens in the UK offers a range of top class services that add value to customers' work. A customer can buy raw materials from any supplier. The cheapest supplier, however, may not have access to technical expertise and high levels of service.

Siemens offers highly technical products with service benefits added in. This sort of service capability drives a competitive advantage over other suppliers. This is a deliberate strategy.

Siemens in action

Siemens in the UK designs and makes super-conducting magnets for body scanners worldwide and more than a third of all MRI scanners in hospitals have a Siemens magnet at their heart. These are made in the UK.

Variable speed drives; industrial gas turbines; motor parts and rail communication systems are UK-produced. These are for the world market. Siemens traffic management systems manufactured in the UK are exported to places as far afield as China, Malaysia, Bahrain and Brazil. In 2005, exports of manufactured goods totalled £500.4 million and accounted for 16% of sales.

However, for Siemens in the UK the trend towards service provision seems unstoppable, because this is what customers want. It is easier to differentiate services than products because many products can become commodities.

The UK National Health Service (NHS) is Europe's largest organisation. Using private sector specialists, NHS Hospital Trusts in the UK are modernising healthcare.

Siemens is working with NHS Trusts and other partners to create brand new hospitals. In Barnet and Chase NHS Trust, it has embraced a 33-year Private Finance Initiative (PFI). The company is providing Accident & Emergency units, medical equipment, communications, intensive therapy units and several operating theatres.

Within these facilities, Siemens is creating hospital IT and energy management systems. These systems can integrate patient records with an electronic picture archive. This helps to improve hospital efficiency at every level. This saves lives and makes clinical decisions easier.

To raise standards of service, Siemens employs on-site contract managers to look after customer relationships and technology. This means that each customer's requirements are unique. There is not an off-the-shelf solution for all. There is an individual response to need, based on detailed interaction with a customer.

Conclusion

Siemens' aim is to be profitable. It seeks to be a global leader in electronics and electrical engineering. Because of this, it works within a huge range of industrial sectors. All over the world, electrical equipment controlled by Siemens electronic systems is in use.

In the UK, Siemens provides the full spectrum of products and services and, in terms of its turnover, the UK is the third biggest market in the world for Siemens. The company structure is such that it can look after local interests whilst drawing on global resources.

Although the global Siemens HQ is based in Germany, Siemens in the UK is responsible for looking after the UK market. Local management is empowered to create relationships with customers.

Company culture encourages new and better methods of meeting local needs.

Siemens continually acquires new businesses to offer what its customers need, which is increasingly end-to-end integrated solutions that allow them to concentrate on their core business. Siemens both in the UK and globally is a dynamic and responsive business.

A Vodafone case study

“USING TECHNOLOGY TO IMPROVE ECONOMIES”

Introduction

Introduction

Vodafone is a leading international mobile communications company with interests in 27 countries and partnership agreements with a further 40 countries, including Safaricom in Kenya. It has over 71,000 employees throughout the world and in 2008 had more than 289 million customers. In the UK, more than 19 million people use Vodafone services.

Vodafone's vision is 'to be the world's mobile communications leader' and a key component of this is to ensure that customers trust and admire the company. It achieves this by taking a responsible approach to the way it conducts its business. This enhances its reputation and builds customer loyalty. Vodafone's business strategy and its Corporate Responsibility (CR) strategy are interlinked. Vodafone believes that long-term commercial rewards come from doing business in a sustainable way.

Vodafone's approach to business is two-fold:

- to provide product extension - new features, dimensions and services in saturated markets. These are areas like the UK, USA and Europe which have sophisticated users who want and expect new functions from their mobiles. Developing new ways of delivering products and services helps to keep existing customers and attract new ones. For example, 3G technology has improved the ability and quality of transferring voice and data. Very fast internet speeds allow extended services such as video calling, music downloads, mobile television and email messaging;

- to look for opportunities in emerging markets. These include some of the world”s more remote areas, including parts of Africa, where many people do not yet have access to a mobile phone. The less developed infrastructure in these areas makes traditional landline telecommunications difficult. Vodafone is committed to providing these markets with the technology to develop communication that will help both economically and socially. There are now more than four billion mobile phones across the world and 64% of all users live in a developing country.

This case study highlights Vodafone's activities in different types of economies and the impact of technology on both developed and developing markets.

What is an economy?

An economy is a system which tries to balance the available resources of a country (land, labour, capital and enterprise) against the wants and needs of consumers. It deals with three key issues:

- what is produced;

- how it is produced;

- who gets what is produced.

There are three main types of economy: planned economy, market economy and mixed economy. Planned (also known as command) types of economies were found in previously communist countries, such as Romania, Bulgaria and Russia, and in North Korea today. In a planned economy the government makes all decisions for society. Producers only make what they are instructed to make. The main benefits are that most workers are employed and most people enjoy a similar basic lifestyle. The problems, however, may be far-reaching:

- a planned economy gives little capacity for development, so growth and investment is limited;

- the infrastructure is usually under-developed as government spends on other areas such as defence;

- wages are state-controlled, so people have less motivation to perform at higher levels;

- prices are fixed by government. Consumers often cannot afford luxury goods such as computers or mobile phones, which are taken for granted in developed countries.

In market economies (also known as free enterprise) the government's role is limited to providing legislation to protect businesses and consumers and making sure no single business or organisation restricts competition. It also provides essential services (like police and defence) and ensures the country's money supply is stable. The main features are:

- businesses are motivated by profits to make products that customers will buy;

- customers' demand for products and services affects the levels of supply and the pricing;

- if customers do not buy and demand falls, then a business must make less, be more efficient or produce an alternative product.

There are few, if any, examples today of countries with a purely free market economy. A purely market economy could have several drawbacks. It could lead to inequality in society. For example, those who can afford to pay for health care receive it, those who cannot pay, do not. In times of economic crisis, without government intervention, many businesses, such as major banks which have a fundamental role in the nation's economy, would fail.

The mixed economy is a combination of both planned and market economies. Most countries demonstrate a mixed economy, including the most developed countries like the UK and the USA. Even a communist country like China has an economy which relies on a mixture of state and private enterprise:

- in a mixed economy, the government contributes and controls some resources and the market controls the rest;

- the proportion of each contribution may vary. For example, in some Scandinavian countries, the state provides a very high level of social benefits but charges high taxes. In the USA, public benefits (such as free national health care) are minimal. The UK position is somewhere in between.

Developed economies

Developed mixed economies such as the UK produce large numbers of goods and services to meet consumer needs. This sector represents the top of the socio-economic pyramid. In this type of economy, where customers have choice, Vodafone needs to  differentiate itself in the market. It relies on its strategic mix of innovation in products and services, customer focus and its responsible approach to business to meet consumer demand and develop long-term customer relationships.

differentiate itself in the market. It relies on its strategic mix of innovation in products and services, customer focus and its responsible approach to business to meet consumer demand and develop long-term customer relationships.

Vodafone's business model is market-orientated and customer-focused. It researches customer needs and desires and produces products and services to meet those needs. For example, in the UK's developed market, Vodafone provides its customers with the benefit of:

- network coverage for calls and data across almost 100% of the population;

- a wide range of handsets and airtime plans to suit every type of customer and use;

- access to messages, email, the internet and the sharing of images, videos and music through mobile phones.

In developed economies, mobile phones are considered a normal part of life and the functions they provide add value to landlines. Customers expect increasingly sophisticated products. Vodafone's integrated mobile system can be used for business, education or socialising. The latest handsets allow people to keep in touch with family and friends through emails, messaging and networking sites such as Facebook and Twitter. They can research and develop their interests online or play games, listen to music or watch TV in any location.

Developing economies

Developing economies are those countries in the middle or bottom layers of the socioeconomic pyramid. These countries often face great difficulties in improving their economies. For example, in planned economies, assets like land or property are owned by government. Individuals and businesses are not used to making decisions and operating to make a profit. When Bulgaria moved from its previous planned economy to a mixed economy at the collapse of the Soviet Union, its agriculture, banking system and industry were not able to support the levels of output the economy needed. However, with investment, economic growth is now growing at a steady rate and Bulgaria was able to join the European Union in 2007.

Developing economies, like many emerging African nations, may also be market economies but share features which hold them back:

- the population lives on very low incomes (typically less than $2 or about £1 per day);

- poor infrastructure such as transport (roads or railways) or local government;

- poor communication systems;

- low levels of basic health and education;

- a low Gross National Product (GNP).

Kenya is a developing market economy. Its infrastructure and communications are extremely poor. Over 75% of the country's workforce is in agriculture which can be affected by the climate. Telephone landlines are scarce, expensive and difficult to install. Kenya has just 450 bank branches which are based in cities and tourist areas. 80% of Kenyan adults have no bank account. Many of these are self-employed business people, such as small farmers. Only 27 % have access to a bank because of the remote distances involved. In addition, theft is a problem in many areas. These problems mean that small businesses find it difficult to operate.

Conclusion

Vodafone uses the capabilities of the mobile phone to bring value to both developing and developed economies. The impact of mobile technology on developed markets over recent years has been immense and has focused on providing added value to customers through new and improved functions and features. By comparison, the impact of technology on emerging markets such as Kenya has provided a real lifeline both to individuals and to small businesses. The mobile phone has helped economic development in emerging economies. With growth in the provision of mobile phones, Vodafone has enabled great improvements in facilitating the flow of money and information, which is vital for economic growth.

By improving Kenya's telecommunications infrastructure and by providing the M-PESA system, Vodafone has enabled more people to access and transfer money. This has also helped socially by helping people to take advantage of employment opportunities away from their home towns and villages.

A Cadbury Schweppes case study

“FINANCIAL STATEMENTS AND REPORTING”

Introduction

Limited companies (those owned by shareholders) are required by law to produce Financial Statements. These statements must be published and made available to shareholders as part of a company report. Cadbury Schweppes aims to produce clear financial statements that give a valuable insight into the company's strategy and performance.

Cadbury Schweppes is a major international company that manufactures, markets and sells confectionery and non-alcoholic beverages. With origins stretching back over 200 years, Cadbury Schweppes' brands are enjoyed today in almost every nation in the world. They include regional and local favorites such as Cadbury Dairy Milk, Trident, Halls, Dentyne, Bubblicious, Bassett's and Trebor in confectionery and Dr Pepper, Schweppes, Snapple and 7Up in beverages. The company employs around 50,000 people.

Cadbury Schweppes' Head Office accounts team collects the information required to create these statements from the company's accountants and financial teams around the world. The legal responsibility for producing financial statements that present an accurate picture of the company's performance over the period lies with the company's directors.

These statements must be checked by an external audit, where the company hires a firm of accountants to verify that it provides a true and fair record and complies with legal requirements. The exact statutory requirements for limited companies to prepare and publish accounts are laid down for limited companies through the Companies Act 1985, regulated by Companies House, and for publicly listed companies through European law, the Listings Rules, regulated by Financial Services Authority (FSA).

Some leading public companies, like Cadbury Schweppes, include reports to shareholders on their success in meeting self-set financial goals within their financial statements. The three main Financial Statements are:

- Profit and Loss Account;

- Balance Sheet;

- Cash Flow Statement.

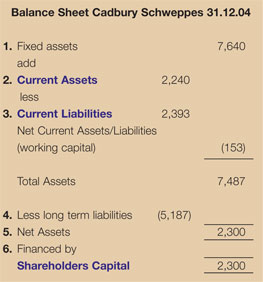

The Balance Sheet

To understand the financial position of Cadbury Schweppes at a moment in time, it is necessary to 'freeze' the values of various financial components. These values, or balances, are used to set out the Balance Sheet.

A Balance Sheet shows the relationship between the assets of the business (what the business owns or is owed), and the liabilities of the business (what the business owes). When liabilities are taken away from assets this gives a figure for net assets, which provides an indication of the health of the business at a point in time.

A Balance Sheet shows the relationship between the assets of the business (what the business owns or is owed), and the liabilities of the business (what the business owes). When liabilities are taken away from assets this gives a figure for net assets, which provides an indication of the health of the business at a point in time.

The chart shows a summarized Cadbury Schweppes Balance Sheet for 2004. It sets out the overall structure of the Balance Sheet, but simplifies some of the individual balances. Here is a simple explanation of the Balance Sheet.

1. Fixed assets consist of two main elements.

Intangible Assets are ones that help to generate wealth for the business over time but don't have a physical presence. For example, a major intangible for Cadbury Schweppes is the 'goodwill' associated with brands that it has acquired, such as Halls. The fact that Halls is an existing high profile brand that consumers recognize and connect with gives Cadbury Schweppes a valuable asset that will generate sales and profits over a long period. Internally generated brands, like Cadbury Dairy Milk, are not on the balance sheet as they have not been purchased at a known cost.

Tangible assets are those that exist physically; these include the costs of factories and machinery used to make the products and the offices that the staff work in around the world.

2. Current assets consist of stock (Inventories), trade and other receivables (Debtors, i.e. amounts of money customers owe for goods that they have not yet paid for), and cash. After production, supplies of chocolate and sweets are stored for a short period of time until a customer makes an order when they are delivered to wholesalers and supermarket chains such as Tesco. Stocks are counted as current assets because they are quickly turned into cash. Tesco and others typically buy from Cadbury Schweppes on credit - the money owed is counted as a current asset, and the company owing it is a debtor.

We then deduct the liabilities (see point 3) from the assets.

3. Current liabilities consist of any payments that Cadbury Schweppes must pay out in the short-term (typically under a year) such as payments to suppliers for cocoa and sugar. In addition, it would include short-term borrowings and overdrafts.

4. Non-current liabilities consist primarily of bank loans, money owed to employees to pay their pensions, etc.

5. The net assets/liabilities figure is then calculated by deducting the two main types of liabilities from the two main categories of assets.

6. The final section of the Balance Sheet shows the amount of shareholders' funds. This is the price paid by the shareholders for their initial share capital and the retained profits made by the company.

At the end of 2004 the net assets of Cadbury Schweppes and thus the total equity (shareholders' capital) was £2,300m. Visit The Times 100 website for updates, which will be released as soon as the results for 2005 are available.

Cash flow statement

In addition to the Balance Sheet and Income Statement, Cadbury Schweppes values the information provided in its Cash Flow Statement. This statement simply sets out the incomings and outgoings of cash in a business during a particular period of time e.g. one year. It shows how the main categories of cash flow have changed the cash balance in particular periods.

In 2004, Cadbury Schweppes achieved free cash flow generation of £265 million. Cash flow is very important to the company because cash enables the business to pay its bills, pay dividends to its shareholders and, in addition, to make acquisitions.

In recent times Cadbury Schweppes has focused on acquiring new businesses, increasing sales and innovation, cutting costs, and integrating existing businesses to achieve its aims of:

- higher sales growth

- improved operating profit margins

- higher levels of free cash flow.

Through efficient financial management Cadbury Schweppes is able to continually invest in making sure that customers are supplied with the brands that they enjoy.

Conclusion

Cadbury Schweppes prepares financial statements because:

- As a listed company, it is legally required to do so.

- Cadbury Schweppes wants to communicate a true and fair picture of the financial state of the company to its shareowners and external analysts.

- The company values transparency and honesty and aims to reflect this is all its communications, both internally and externally.

Cadbury Schweppes won the Communication of Corporate Strategy Award at the PricewaterhouseCoopers 'Building Public Trust' awards in 2005. This publicly recognized the high standards of the company's reporting: 'a highly accessible overview of its short-term strategy, major markets and measurable targets.'

A Nestlé case study

“SUSTAINABILITY AND WATER”

Introduction

Intelligent businesses in the 21st century operate with an awareness of their responsibilities to all of their stakeholders, not just responsibilities to directors and shareholders, but also to customers and, perhaps most importantly, the environment. For Nestlé, this is nothing new. From its founding in 1867 by Henri Nestlé – who developed the first cereal-milk food for infants – Nestlé has built its business on the basis of sound principles. The business is committed to creating value for all stakeholders and recognises that different stakeholders see different values as important.

The major stakeholders in Nestlé are:

- shareholders, who want a dividend from profits

- employees, who want job security and the necessary training and development to allow them to further their careers with Nestlé

- consumers, who want products that better meet their needs, that are available in the right places and at the right price

- business partners, who want long-term and trusted relationships

- local and national economies within which Nestlé operates.

This Case Study examines Nestlé’s policies on eco-efficiency and sustainability, and, in particular, how it has developed a responsible policy towards the use of water. This is covered in its first water review ‘Nestlé and Water: Sustainability, Protection, Stewardship’ published in 2003.

Background

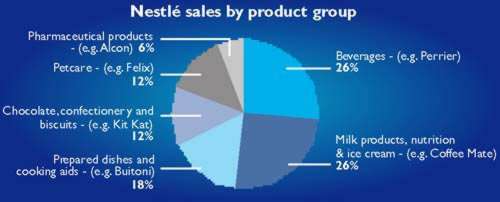

Nestlé is the world’s largest food and beverage company and employs over a quarter of a million workers. It is in the secondary sector at the center of the supply chain that starts with producers of agricultural products in the primary sector and ends with distribution and retailing in the tertiary sector.

Nestlé is the world’s largest food and beverage company and employs over a quarter of a million workers. It is in the secondary sector at the center of the supply chain that starts with producers of agricultural products in the primary sector and ends with distribution and retailing in the tertiary sector.

Ownership

Nestlé SA acts as a holding company. SA is the Swiss equivalent of a UK public limited company (plc). Like all companies it has a duty to provide returns to its shareholders in the form of dividends. Nestlé balances this against the need for growth whilst continuously improving and being true to its principles of sustainability. Nestlé UK is a private limited company (Ltd), wholly owned by Nestlé SA. However, Nestlé UK has its own directors and can make many of its own decisions; this is because Nestlé strives to be as decentralized as possible - local decisions are made locally.

Nestlé SA acts as a holding company. SA is the Swiss equivalent of a UK public limited company (plc). Like all companies it has a duty to provide returns to its shareholders in the form of dividends. Nestlé balances this against the need for growth whilst continuously improving and being true to its principles of sustainability. Nestlé UK is a private limited company (Ltd), wholly owned by Nestlé SA. However, Nestlé UK has its own directors and can make many of its own decisions; this is because Nestlé strives to be as decentralized as possible - local decisions are made locally.

Nestlé produces over 100 brands, including many household names such as Nescafé, KitKat and Nesquik. Other brands are also well known, but you might not have realized that they were Nestlé products - such as Golden Grahams, Buitoni, Friskies and Perrier. In 2002 Nestlé had a sales turnover of over £38.3 billion on which it made a net profit of over £3.2 billion. The majority of this profit (63%) was re-invested in the business whilst the remainder was paid out to shareholders in dividends. Its attitude to growth is that it, too, should be sustainable, and this usually means organic growth. However, its water business - known as Nestlé Waters since 2002 - has grown both organically and by acquisition. Nestlé acquired Vittel in 1969, Perrier in 1992 and San Pellegrino in 1998. Today, Nestlé Waters is established in 130 countries and is the world’s leading bottled water business.

Acting responsibly

Nestlé feels that it has a real role to show a lead in acting responsibly with its business partners, suppliers and customers around the world. Responsible business practices don’t just make moral sense; they make good business sense. The company has therefore developed policies and principles to help it meet its general aims of fairness, honesty and concern for people. Its Corporate Business Principles includes all nine principles of the United Nations Global Compact referring to labor standards, human rights, and the environment which are applied throughout the company.

Some of the basic Nestlé values and principles are to:

- prefer long term development over short term profit

- develop long term commitments and relationships with suppliers and customers

- show respect for diverse cultures and ensure operations integrate with them

- recognize that consumers deserve information about the products they buy and the company behind the brand

- encourage all employees, led by senior management, to follow these principles by integrating them into Nestlé’s business processes.

Nestlé and sustainable development

Nestlé defines sustainable development as “the process of increasing the world’s access to higher quality food, while contributing to long-term social and economic development, and preserving the environment for future generations”. Nestlé tries to be a genuine partner in sustainable development. The rise in the world’s population means there is an increased demand for food. This in turn places pressure on water and raw materials produced by the primary sector. If Nestlé wants its business to continue growing it must encourage more production of better quality raw materials from its suppliers. Recognising that others face this issue, Nestlé created the Sustainable Agricultural Initiative with other food manufacturers. The group defines sustainable agriculture as “a productive, competitive and efficient way to produce agricultural raw materials, while at the same time protecting and improving the natural environment and social/economic conditions of local communities”. They recognise that this will take time, but by co-operating these competitors are better placed to make an impact on a global scale.

The basic economic problem

Economists distinguish between wants and needs; needs are those things which people require to survive. These comprise food, water and protection from the elements in the form of shelter and clothing. Nestlé products fall into two of these categories (food and water). However they can only be described as wants because it is possible to survive without consuming any Nestlé products at all.

All resources are considered scarce because the wants for them (the demand) outstrip the various uses for them (the supply). This means that they have to be shared out (distributed) by a mechanism such as price. There are numerous ways in which a resource may be used, an opportunity cost is therefore created whenever one use is preferred over another. If water is used for industrial production, it is not available for agriculture or domestic consumption. Water is a classic example of the distribution problem of scarce resources. There is actually enough water in the world for everyone’s needs, and it is not a resource that is ever ‘used up’ in the way that other resources can be consumed. The amount of water in the earth’s water cycle – evaporating from the sea, then falling as precipitation over land – is constant, the problem is one of distribution - it is not always located where it is needed.

Factors of production

The factors of production are:

- land - natural resources including water and the proportion of the planet given over to agriculture producing raw materials

- labor - the human effort involved in production

- capital - the money invested in business including equipment purchases

- enterprise - the process of bringing the above factors together to make a profit.

Any production process involves the use of all factors of production. The efficient and sustainable use of factors of production has long been tackled by Nestlé working with its agricultural suppliers. Nestlé helps suppliers in developing countries to increase their output. For example, in Pakistan sales of milk per farmer have doubled in the last three years as a result of the support from Nestlé Agricultural Services provided to more than 115,000 farmers.

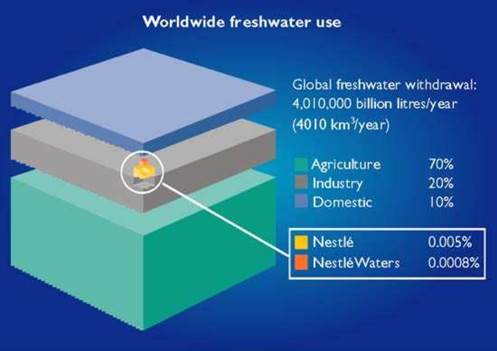

Despite consuming only a tiny proportion of water, (see table) Nestlé still seeks to minimize water use. 70% of water usage is by agriculture, and agricultural raw materials provide the basis of Nestlé’s finished products. It is important that the environment in which raw materials are grown is safeguarded and protected in a sustainable manner. Nestlé does not own farms but encourages sustainable agricultural practices amongst its suppliers. The company invests over £45 million per year in environmental protection, amounting to 3% of total capital expenditure on top of regular capital-investment projects that incorporate environmental components and factory environmental operating costs. Also, in certain parts of the world, Nestlé has invested in water education programs and community initiatives to develop sustainable and safe water supplies. It partners EcoLink - a non-profit-making, non-government environmental education trust - in a water tank project to provide a reliable source of clean water to many South African communities. For example, in the Nkomazi and  Nsikazi areas 20 water tanks have been provided at various women's groups and schools reaching over 10,600 people. For more information see www.nestle.co.uk/studentissues and follow the links to Nestlé in the Community and the Ecolink page.

Nsikazi areas 20 water tanks have been provided at various women's groups and schools reaching over 10,600 people. For more information see www.nestle.co.uk/studentissues and follow the links to Nestlé in the Community and the Ecolink page.

Nestlé uses water in manufacturing (for example to wash raw materials). It limits the use of water in its various operations and, where this is not possible, re-uses or re-cycles waste water.

Conclusion

Nestlé is not complacent about its position, it still means to go forward, developing new policies and initiatives on eco-efficiency, responsible business practice and sustainability. Nestlé will also work with national and international bodies to improve sustainability. For example, the 2002 World Summit on Sustainable Development set a target to decrease by half the number of people without access to safe drinking water by 2015: Nestlé will share its knowledge with others to help reach this goal. Nestlé will continue to protect water, increase the efficient and responsible use of water and encourage its partners and stakeholders to use water in a responsible way.

A Nissan case study

“PLANNING FOR QUALITY AND PRODUCTIVITY”

Why locate in Sunderland?

One key decision with a car plant is where to locate it. For its UK factory, Nissan chose in 1984 a 300 hectare former airfield near Sunderland. Sunderland's attractions included:

a) Skilled labour force

Manufacturing has a long tradition in the area. A decline in other local manufacturing meant that skilled labour was readily available.

b) Communications

Sunderland has good road and rail links to all major UK areas. This makes it relatively easy to bring in supplies from 105 separate UK component and sub-assembly suppliers, and also to distribute completed vehicles. A nearby deep water port (Port of Tyne) gives ready access to export markets and for the import of vehicles to the UK.

c) Government support

The government provided financial and other incentives to manufacturers who set up in an area where employment opportunities had reduced sharply and new jobs were needed.

Since 1984, Nissan has increased the scale of its Sunderland operation; almost 3.5 million cars have already been made.

Production

Car assembly is a complex operation with many components requiring skilled assembly. That's a crude indication of what is involved. Management are particularly keen to monitor total machine-hours and total labour-hours that each vehicle requires.

Car assembly is a complex operation with many components requiring skilled assembly. That's a crude indication of what is involved. Management are particularly keen to monitor total machine-hours and total labour-hours that each vehicle requires.

So far, Nissan has invested over £2.1 billion in the Sunderland site, taking its production capacity to 500,000 vehicles per year.

Production methods must be able to produce what customers want, in the quantities customers require, at a price consumers are willing to pay, and at a cost that yields a profit to the business. That means that being efficient is vital to success.

In some industries it is possible to carry out individual job production to meet a particular customer's request e.g. a wedding dress, a birthday cake, a fitted kitchen. However, very nearly all of the world's car manufacturers mass produce standard models, with individual consumer choice being accommodated by offering various colours, interior designs, and optional extras within a limited flexible production process. People can still personalise their cars further e.g. by choosing a particular car registration or accessories.

In pursuit of high output at low average cost, car manufacturing typically uses a continuous flow production method, where sub-assemblies are brought together in a final assembly area. This is the most cost effective and efficient method of production and the speed of the final assembly line can be adjusted to match consumer demand. If demand picks up, the production line can be accelerated, within predefined limits.

At NMUK, the production flow draws on three main production shops, as well as support areas. The three main shops are:

At NMUK, the production flow draws on three main production shops, as well as support areas. The three main shops are:

- body assembly

- painting

- final assembly.

Supporting manufacturing areas are:

- press shop - produces panels for the vehicles

- plastics shop - makes bumpers (fenders) on site

- castings shop - makes engine parts e.g. cylinder heads

- engine shop - assembles engines, installs oil, coolant fuel

- axle plant - produces axles that are joined to engines in final assembly.

Widely different processes generate different jobs across three main broad areas.

The machinery is scheduled to work at a given level although when demand requires it; there is flexibility in regard to both the machinery and the workforce of 4,300. At the moment, with a two-shift pattern, NMUK has a total production capacity of around 360,000 units/year - a third shift can be introduced which would take production up to 500,000 units/year if and when required.

The machinery is scheduled to work at a given level although when demand requires it; there is flexibility in regard to both the machinery and the workforce of 4,300. At the moment, with a two-shift pattern, NMUK has a total production capacity of around 360,000 units/year - a third shift can be introduced which would take production up to 500,000 units/year if and when required.

Flow production

Nissan's Sunderland plant is technically highly advanced. It uses sophisticated robotics and computer integrated manufacturing techniques to create a carefully monitored production process that reduces errors to an absolute minimum.

Automated machines can only do so much however; the human element remains vital. Organising an effective flow of production at Nissan has involved developing a way of doing things and an attitude towards work based on giving responsibility to employees at every step. This approach raises employees' morale, and reduces absenteeism, which could severely impact on continuous flow production.

Nissan expects and requires its employees to become multi-skilled decision makers. Most employees also want that for themselves. Reaching that goal involves:

- training employees to develop their skills;

- encouraging them to make decisions;

- organizing employees into participative teams;

- developing open-channel, multi-directional communication systems;

- placing quality at the heart of flow production;

- flexible working practices;

- providing the employee variety within his/her role.

The open communication policy includes daily face to face meetings between management and employees, a company council, employee surveys, and employees having ready access to the company's intranet system.

The emphasis placed on 'going for quality' means that each employee is responsible both for their own work and the standards of their co-workers. By ensuring management recognises that individuals have this control results in everyone taking the culture on board.

'Going for quality' emphasises 'building good quality in' rather than 'inspecting poor quality out'. Each employee controls quality by checking that the previous job has been done properly.

Total Quality Management

Total Quality Management (TQM) is a key feature of Nissan's way of working. TQM involves making customer satisfaction top priority. Given this goal, everything the organisation and its people do is focused on creating high quality. To achieve this, Nissan has to:

- understand customer requirements;

- consider the processes involved in providing quality, not just the end result;

- prioritise and standardise tasks to deliver quality;

- educate all employees to work in this way.

In practical terms TQM involves:

- identifying customers and their requirements;

- establishing and using objectives (targets) for all areas of activity;

- basing decisions on researched hard facts rather than on hunches;

- identifying and eliminating the root causes of problems;

- educating and training employees.

TQM is an on-going process; a way of thinking and doing that requires an 'improvement culture' in which everyone looks for ways of doing better. Building this culture involves making everyone feel their contributions are valued and helping them to develop their capabilities.

A cycle of Plan, Do, Check, Action becomes part of every employee's thinking, because it represents Nissan's way of working.

Just-in-time technology

With a just-in-time approach, specific vehicles and their components are produced just-in-time to meet the demand for them. Sub-assemblies move into the final assembly plant just as final assemblers are ready to work on them, components arrive just in time to be installed, and so on. In this way, the amount of cash tied up in stocks and in work-in-progress is kept to a minimum, as is the amount of space devoted to costly warehousing rather than to revenue-generating production. Nissan's just-in-time process depends not on human frailty but on machine precision.

Every vehicle is monitored automatically throughout each stage of production. A transponder attached to the chassis leg contains all of a vehicle's production data e.g. its required colour, specification and trim. This triggers sensors at various points along the production line thus updating the records.

When, for example, the transponder sends a message to the production system at a supplying company to produce a seat in a particular colour and trim, this triggers the relevant response and a seat to the required specification is produced. Further along the production line the specifically produced seat arrives to meet the vehicle to which it belongs - just in time.

The importance of training

It is vital to train people to work in such a hi-tech industry with such sophisticated quality systems. NMUK's training department conducts a training needs analysis to assess individual employees' needs and to organise training programmes.

The department concentrates on five main areas:

1. technical development - e.g. teaching skills relating to robotics and electrics, plus the required knowledge e.g. wiring rules/regulations.

2. people development - identifying employee needs and ambitions; providing courses to help personal development e.g. in team building and communication skills

3. understanding processes - workshops covering safety, production operations etc

4. computer skills and graduate training - from basic to highly technical

5. trainee development - courses for graduate trainees ranging from accountancy to team building.

Kaizen

Nissan is famously associated with 'Kaizen' or continuous quality improvement. Nissan states: 'We will not be restricted by the existing way of doing things. We will continuously seek improvements in all our actions.'

Kaizen can be applied everywhere, any time, any place. It can involve the smallest change in everyday working practice as well as a major change in production technology. Typically these improvements are initiated by teams of employees sitting down together and sharing ideas for improvements. Small steady changes are maintained to make sure that they actually work. No improvement is too small. Everyone at Nissan is responsible for thinking about the current way of doing a job and finding a better way of doing things.

Kaizen improvements can save:

- money;

- time;

- materials;

- labour effort;

as well as improving quality, safety, job satisfaction, and productivity.

Kaizen permeates the NMUK suggestion scheme, which offers not financial or individual rewards but items that benefits the whole team e.g. a microwave for the staff kitchen, a pool table for the canteen.

Conclusion

Productivity levels at Nissan's plant in Sunderland, and the quality of final production there, have not happened by chance or good fortune. They stem from an all-embracing approach to a production process, designed to bring out the best in both people and machines. It continues to be conspicuously successful.

A McDonald's Restaurants case study

“RECRUITING, SELECTING AND TRAINING FOR SUCCESS”

Management Development

The McDonald's Management Development Curriculum takes new recruits from trainee manager to Restaurant Manager. This consists of on-the-job training and open learning development modules, supported by courses and seminars at the Company's National and Regional Training Centres. The Management Development Curriculum is aimed at persons aged 21 or over, either graduates or individuals with some previous management experience. It offers a direct route into restaurant management, through an intensive structured training programme. The Management Development Curriculum is divided into four key programmes:

- Shift Management - developing trainee managers in the skills and techniques required to become effective in all aspects of running a shift.

- Systems Management - targeting second assistant and newly promoted first assistant managers. This programme covers all areas of McDonald's systems, increasing the manager's business knowledge. It also develops individual techniques.

- Restaurant Leadership - introducing managers to the key skills needed to become effective restaurant leaders e.g. team-building, communication, decision-making.

- Business Leadership - focusing restaurant/general managers on the need to develop a business strategy that encompasses both internal and external factors.

Most departments in the regional offices offer restaurant managers opportunities to be seconded to work in the regional office. This gives an experienced manager the opportunity to develop and learn new skills, to see a different side of the business and to experience how each department's strategies have a role in achieving the company's goals.

Conclusion

McDonald's believes that the success of the restaurants and the company is achieved through the people it employs. The company aims to recruit the best people, to retain them by offering on-going training relevant to their position and to promote them when they are ready. Its recruitment policies, procedures and practices reflect the company's determination to fulfil its aim.

A Coca-Cola Great Britain case study

“WORKING WITH BOTTLING FRANCHISEES

AROUND THE WORLD”

Introduction

The Coca-Cola Company is the world's largest beverage company and is the leading producer and marketer of soft drinks. Today, Coca-Cola is consumed throughout the world at the rate of more than 600 million times per day and this figure is continuing to rise. However, Coca-Cola is not the sort of company to live on its past glories; instead it looks to the future as a challenge and constantly seeks new markets and ways of increasing its market share in areas where it currently has a strong presence. It is the world's largest producer and distributor of syrups and concentrates for soft drinks. Products developed by the Company are sold through bottlers, fountain wholesalers and distributors around the globe. Brand Coca-Cola accounts for about 75 per cent of the Company's unit sales volume of soft drinks. The remaining 25 per cent consists of well known soft drinks such as Sprite, Fanta, Fresca, Mello Yello, Surge, POWERaDE, Barq's Root Beer and many other brands. The Company's soft drink operations are managed in 6 Groups: North America, Latin America, Africa, Greater Europe, Middle/Far East and The Minute Maid Company (the world's leading marketer of fruit juices and fruit drinks).

Just a few years ago, Coca-Cola attracted frequent headlines as consumers in China, India, Eastern Europe or Russia tasted Coca-Cola for the first time. Now however, Coca-Cola has become a well established soft drinks product for billions of new consumers throughout the world. Today, the challenge facing The Coca-Cola Company is to establish successful patterns of distribution to its global consumers. This case study therefore focuses on the ways in which high quality relationships have been established with bottling franchisees across the globe to make sure that consumers' needs and wants can be met in the most effective way.

Division of responsibility

The company ships syrup or concentrate to the bottling plants where the franchisees mix it with sugar and treated local water and carbonate it. The water is purified to the highest standards using equipment specified by Coca-Cola. Samples are taken regularly for chemical analysis and Coca-Cola staff make frequent spot checks to ensure that plants are maintaining the company's standards of cleanliness and quality. Coca-Cola provides its franchisees with access to 'state of the art' equipment needed to meet the Company's exacting standards.

Each bottler or canner supplies Coca-Cola and other company products to the retail trade. Standard outlets include supermarkets, sweetshops, restaurants, off-licences, pubs and bars. These outlets often sell Coca-Cola from vending machines and coolers which the franchisees must supply and service. There is a clear division of responsibility between The Coca-Cola Company and its franchisees as shown in the illustration above:

Coca-Cola Enterprises

Coca-Cola Enterprises is a publicly quoted company (on the New York Stock Exchange) and is the largest franchisee of Coca-Cola products. In addition to its operations in the United States, CCE holds the franchise for Belgium, The Netherlands, Great Britain and 90of France. Early in 1997, it acquired full ownership of Coca-Cola & Schweppes Beverages Ltd. It is therefore the largest of what Coca-Cola calls its 'anchor' bottlers. Coca-Cola Enterprises employs almost 50,000 individuals who operate the 310 facilities and is responsible for one million vending machines, beverage dispensers and coolers used to market, distribute and produce the Company's products.

Coca-Cola & Schweppes Beverages Ltd has some 3,500 employees in Great Britain with five plants in England (Edmonton and Sidcup in the London area, Milton Keynes, Wakefield and Colwall - where Malvern Water is sourced) and one in Scotland, at East Kilbride. Apart from holding the franchises for the products of The Coca-Cola Company and Cadbury Schweppes plc, CCSB has distribution agreements for such varied products as Appletise, Capri Sun, Perrier and Duchy Originals.

Coca-Cola Enterprises is responsible for bottling and distributing Coca-Cola to the markets it serves. Together with The Coca-Cola Company, it seeks to maintain the highest quality standards so that a consistent, high quality product is produced in each of the countries in which it operates. However, ensuring quality goes well beyond creating a refreshing drink which is instantly recognised as the 'only one Coca-Cola.' Bottlers additionally assume broader corporate responsibilities such as environmental management and they seek to develop and apply standards which go beyond regulatory compliance in this area.

The future of Coca-Cola depends on the relationships built by its bottling franchisees with the wholesalers and retailers they supply. Strong and enduring relationships in the supply chain leading to the consumer are of vital importance. For Coca-Cola Enterprises, this involves listening carefully to wholesalers and retailers to find out what sorts of product requirements they have - e.g. what size of containers and what types of packaging are most likely to sell in retail outlets.

Coca-Cola Amatil

Coca-Cola Amatil is the second largest of The Coca-Cola Company's international bottling partners which today operates in 18 countries throughout Australasia, South-East Asia, Central and Eastern Europe. It serves a market of over 450 million people and is No. 1 in every market in which it operates. Some of these markets are relatively mature in terms of opportunities for future sales expansion e.g. Australia and New Zealand, but others such as Poland, the Philippines and Indonesia, are growing at a fast pace. Coca-Cola Amatil is continually seeking to expand where new opportunities arise - particularly in Eastern Europe and South-East Asia. To meet increasing demand for capacity in Ukraine, for example, a large greenfield production facility is being completed in Kiev in 1997, as well as a new plant in Minsk, Belarus.

Coca-Cola Amatil is committed to the highest quality standards and has developed rotating environmental audits, intensive training of personnel at plant level and a continuing commitment to waste minimisation through all stages of production and distribution. The Company's environmental management initiatives have been recognised in Indonesia, where the Medan plant was presented with the Green Award for outstanding environmental efforts in both 1996 and 1997. CCA's plants in Brisbane and Perth were also commended by government authorities for their achievements in water conservation and recycling of waste water. These achievements highlight the important relationships that Coca-Cola has built with its bottlers throughout the world. Franchising arrangements involve a sharing of responsibility for products and corporate image. Organisations are only as successful as their public image. It is therefore essential for Coca-Cola to develop clear and well-thought-out partnerships with top quality bottling franchisees if it is to continue to remain the world's number one soft drinks company.

In many of the countries in which Coca-Cola Amatil operates, home consumption of Coca-Cola has been developing. In simple terms, consumers in South-East Asia and Eastern Europe are beginning to purchase supplies of Coca-Cola to enjoy in their own homes. Beverages purchased for home consumption already constitute around half of the total soft drink volume sold in the Australian and U.S. markets.

Conclusion

The Coca-Cola Company is continually expanding, working to meet consumers' needs for refreshing drinks. The strength of the Company is based on quality products, the power of the Company brand image and on the relationships that Coca-Cola has built with its franchisees and customers. Consumers want to associate with brand names they know and especially with ones which have built high reputations over a period of time. Faced with a choice, the consumer will prefer the brand which they know to be of the highest quality.

A Levi's case study

“RECLAIMING THE IDENTITY OF A BRAND”

Introduction

Levi’s is the best known jeans name on the planet. The business was founded by the Strauss family in 1875 and produced jeans for miners out of tent fabric and canvas. It then went on to make jeans from denim which is a coarse, heavy twill fabric. The jeans became popular with miners during the California goldrush and were famous for the twin rivets on the pockets.

The business went from strength to strength to become one of the twentieth century’s best known global brands. During the 1980s the company branched out into a range of garments including suits, before refocusing on one of its heritage products Levi 501s in the early 1990s. A TV commercial showing Nick Kamen stripping down to his boxer shorts in a launderette boosted the sales of all jeans, not just of Levi 501s and thousands of men switched to wearing boxer shorts.

The Levi Company has always had a reputation for innovation, bright ideas, excitement and enthusiasm. However, it has not always been so successful in maintaining the detailed processes necessary to ensure continued product success - hence the need for effective brand management. Brand management involves having the technical skills to create a successful brand management plan, as well as good ideas.

Implementing decisions

Once brand managers have created objectives and developed the plan, the next step is to implement their decisions, i.e. to put the plan into action.

Levi’s objective is to reclaim the brand. This has involved developing product innovations to excite the relevant target market - empowered young people. A recent product of this process has been the new concept of Levi’s ® Engineered Jeans™; 'twisted jeans'.

A large part of Levi’s advertising and promotion in 2000 is based on this product and is a symbol of youth culture. Unlike earlier Levi’s advertising which had used heroes such as Brad Pitt and Nick Kamen, the emphasis is on the product as 'hero'. Twisted jeans rapidly won the support of young, fashionable people and are representative of Levi’s new way of thinking.

Conclusion

This case study has shown how Levi’s has used effective brand management planning to reclaim the brand and to turn around the fortunes of the company.

This is a logical, step-by-step process which has been implemented by brand managers. The final stage in the process involves the analysis and evaluation of results.

To date, company research reveals that the strategy is delivering equity for the brand which is rapidly regaining its cool and innovative status. The financial targets have also been exceeded.

A Ben Sherman case study

“USING THE MARKETING MIX IN THE FASHION INDUSTRY”

Introduction

Ben Sherman is a globally recognised lifestyle brand. It has grown from its business beginnings in quality shirts in Brighton in 1963 and is now sold in 35 countries around the world. It has expanded into the USA, Europe, and Australasia.

In 2004, Ben Sherman was acquired by the American-based company, Oxford Industries. This group is an international apparel design, sourcing and marketing company that features a diverse portfolio of owned and licensed lifestyle brands.

Ben Sherman's name has always been closely linked with the British music scene and with fashion. Its customers are young and at the forefront of style.

Throughout the years high profile customers include musicians, models, actors and bands, such as Blur, Oasis and the Kaiser Chiefs. The growth of the brand can be traced through changes in musical taste and this is a key part of Ben Sherman's marketing strategy.

As a young person reading this, you are a central market segment of Ben Sherman's target market. A market segment is a group of people with similar needs or characteristics, such as age, gender or lifestyle. For example, you like music, you like fashion and you are willing to spend money on top brands that deliver the quality and image that you want.

As the company founder Ben Sherman said in 1963: 'Looking good isn’t important, it's everything.'

Ben Sherman has developed a balanced marketing mix. This is often referred to as the 4 P”s - product, price, promotion and place. By getting the mix right, the company ensures that its products reach the market segments it is aiming the brand at. This approach helps the business remain competitive and extends its market share and influence.

The marketing mix is like a cake recipe. Most cakes need the basic ingredients of eggs, flour, sugar and milk. However, a child’s birthday cake will require a different recipe to a wedding cake. The key is to combine the ingredients to get the right cake for the right occasion. The marketing mix works in exactly the same way.

The key ingredients of product, price, promotion and place are all necessary for the appropriate marketing of the product. Ben Sherman chooses the right combination of each element to satisfy different customers' needs.

P

|

© 2013 wikipage.com.ua - Дякуємо за посилання на wikipage.com.ua | Контакти |